WO2017168174A1 - New pharmaceutical forms of sildenafil - Google Patents

New pharmaceutical forms of sildenafil Download PDFInfo

- Publication number

- WO2017168174A1 WO2017168174A1 PCT/GB2017/050921 GB2017050921W WO2017168174A1 WO 2017168174 A1 WO2017168174 A1 WO 2017168174A1 GB 2017050921 W GB2017050921 W GB 2017050921W WO 2017168174 A1 WO2017168174 A1 WO 2017168174A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sildenafil

- component

- pharmaceutical composition

- composition according

- crystal

- Prior art date

Links

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/495—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having six-membered rings with two or more nitrogen atoms as the only ring heteroatoms, e.g. piperazine or tetrazines

- A61K31/505—Pyrimidines; Hydrogenated pyrimidines, e.g. trimethoprim

- A61K31/519—Pyrimidines; Hydrogenated pyrimidines, e.g. trimethoprim ortho- or peri-condensed with heterocyclic rings

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0002—Galenical forms characterised by the drug release technique; Application systems commanded by energy

- A61K9/0004—Osmotic delivery systems; Sustained release driven by osmosis, thermal energy or gas

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0002—Galenical forms characterised by the drug release technique; Application systems commanded by energy

- A61K9/0007—Effervescent

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/2072—Pills, tablets, discs, rods characterised by shape, structure or size; Tablets with holes, special break lines or identification marks; Partially coated tablets; Disintegrating flat shaped forms

- A61K9/2086—Layered tablets, e.g. bilayer tablets; Tablets of the type inert core-active coat

- A61K9/209—Layered tablets, e.g. bilayer tablets; Tablets of the type inert core-active coat containing drug in at least two layers or in the core and in at least one outer layer

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P15/00—Drugs for genital or sexual disorders; Contraceptives

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P17/00—Drugs for dermatological disorders

- A61P17/10—Anti-acne agents

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/2004—Excipients; Inactive ingredients

- A61K9/2022—Organic macromolecular compounds

- A61K9/2027—Organic macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polyvinyl pyrrolidone, poly(meth)acrylates

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/20—Pills, tablets, discs, rods

- A61K9/2004—Excipients; Inactive ingredients

- A61K9/2022—Organic macromolecular compounds

- A61K9/205—Polysaccharides, e.g. alginate, gums; Cyclodextrin

- A61K9/2054—Cellulose; Cellulose derivatives, e.g. hydroxypropyl methylcellulose

Definitions

- the present invention relates to novel forms and formulations of sildenafil.

- the present invention relates to the use of such forms and formulations of sildenafil in the treatment of male sexual dysfunction.

- Sildenafil is generically described in US patent 5,250,534 as a selective cGMP PDE inhibitor useful in the treatment of cardiovascular disorders.

- Sildenafil free base i.e. 5- ⁇ 2-ethoxy-5-[(4-methylpiperazin-l -yl)sulfonyl]phenyl ⁇ -l- methyl-3-propyl-l,6-dihydro-7H-pyrazolo[4,3-d]pyrimidin-7-one, is specifically described in US patent 6,204,383 Bl as an agent with pharmaceutical utility in the treatment of male sexual dysfunction.

- Sildenafil free base has the following structure:

- phenol co-crystals improve solubility profile of sildenafil to bring about rapid onset of action.

- the phenol co-crystals improve solubility at all levels of pH therefore improving the performance of the drug during fasted and non- fasted stomach condi- tions.

- Example 1 illustrates the preparation of solid sildenafil by the evaporation of a solution in a mixture of dichloromethane and methanol.

- Examples 2 and 6 describe a solution of sildenafil iodide in dichloromethane, but this is not isolated as a solid product.

- sildenafil citrate The citrate salt of sildenafil (sildenafil citrate) is currently marketed as Viagra® in numerous countries including the USA and the European Union.

- Sildenafil is the active ingredient in Viagra® which is a potent inhibitor of PDE receptors in particular the subtype 5 which is associated with male erectile dysfunction. Sildenafil is a potent muscle relaxant associated with the arterial walls in the cardio vascular system. Sildenafil also antagonises other PDE sub types such as PDE 2 and 6 which are associated with cardiac contractility and blue haze respectively. Whilst Viagra is a very potent and selective drug its pharmacological profile is far from ideal.

- a first step in solving this problem is finding variants of the product, i.e. rapidity longevity and maintenance within the therapeutic window from dose to dose which possess physical and chemical characteristics which are conclusive to addressing one or more of the problems associated with PDE 5 inhibition such as rapidity of action duration of effect and sustenance within the therapeutic window for prolonged periods of time from dose to dose.

- Co-crystals of many substances are known, co-crystals impart properties of the co- crystal partner (co-crystal former, or co-former) on the target molecule.

- co-crystal former or co-former

- Sildenafil is commercially available as the citrate salt and is therefore a good choice as a starting material.

- Other salts of sildenafil have been disclosed in the art however none have been tested for rapidity or duration of effect or for any tendency to be within the therapeutic window from dose to dose.

- the present invention relates to various aspects.

- the invention provides co-crystals of sildenafil with a group of phenolic compounds.

- the invention provides a co-crystal, which co-crystal comprises sildenafil and a co-crystal former, which co-crystal former is a compound which comprises a phenol moiety.

- the co-crystal former may be a compound of formula (I) as defined herein.

- Another aspect relates to fatty acid salts of sildenafil optionally in the form of co- crystals.

- the invention provides a salt of sildenafil with a long chain fatty acid.

- the salt may be amorphous or crystalline.

- the long chain fatty acid typically has formula R-C(0)OH wherein R is Ce-24 alkyl or Ce-24 alkenyl.

- Another aspect relates to a pharmaceutical composition

- a pharmaceutical composition comprising sildenafil and/or a pharmaceutically acceptable salt or co-crystal thereof admixed with excipients in a multicom- ponent pharmaceutical composition, wherein a first component is adapted to deliver sildenafil rapidly to promote fast onset of action, and a further component is adapted to deliver the sildenafil from dose to dose wherein the sildenafil is delivered from dose to dose within the therapeutic window.

- the pharmaceutical composition of the invention may comprise sildenafil and/or a pharmaceutically acceptable salt or co-crystal thereof admixed with excipients in a multicom- ponent pharmaceutical composition, wherein a first component is adapted to deliver sildenafil rapidly to promote fast onset of action, a second component is adapted to deliver the sildenafil from dose to dose, and a third component wherein the sildenafil is delivered from dose to dose within the therapeutic window.

- the pharmaceutical composition of the invention comprises a first component which is adapted to deliver the sildenafil rapidly to promote a fast onset of action, and a second component which is adapted to deliver the sildenafil from dose to dose, and which is further adapted to deliver the active ingredient from dose to dose within the therapeutic window.

- the pharmaceutical composition may be a dosage form, typically a solid dosage form, for instance a swallow tablet.

- the invention further provides a pharmaceutical composition comprising sildenafil or a pharmaceutically acceptable salt thereof, which may be as further defined herein (for in- stance, as in the immediately preceding paragraph) wherein the pharmaceutical composition is in the form of a swallow tablet.

- the dosage form for instance a tablet (swallow tablet)

- a tablet squeeze tablet

- the dosage form comprises two components:

- first component which is adapted to deliver the sildenafil rapidly to promote a fast onset of action

- second component which is adapted to deliver the sildenafil from dose to dose, and which is further adapted also to deliver the active ingredient from dose to dose within the therapeutic window.

- the first component typically comprises from 10% to 30% by weight, for instance 20% by weight, of the total amount of sildenafil in the composition.

- the balance of sildenafil is present in the one or more further components.

- the balance of sildenafil may be present in a second component, or where second and third components are present, the balance of sildenafil is usually distributed between the second and third components.

- the total amount of sildenafil in the pharmaceutical compositions described herein (including in the dosage forms and swallow tablets), is often lOOmg, 50mg or 25 mg.

- the first component typically comprises from 10% to 30% by weight, for instance 20% by weight, of the total amount of sildenafil in the first and second components

- the second component typically comprises from 90% to 70% by weight, for instance 80% by weight, of the total amount of sildenafil in the first and second components.

- the percentage by weight refers to the percentage by weight of sildenafil free base which the particular form of sildenafil provides (i.e. weights are quoted on a "free base" basis).

- the total amount of sildenafil in the first and second components (which again refers to the total amount of sildenafil free base which the particular form or forms of sildenafil in the first and second components provide) is 100 mg, and the first component comprises from lOmg to 30mg of sildenafil and the second component comprises from 90mg to 70mg of sildenafil.

- the first component may for instance comprise 20mg of sildenafil and the second component may comprise 80mg of sildenafil.

- the total amount of sildenafil in the first and second components is 50 mg, and the first component comprises from 5mg to 15mg of sildenafil and the second component comprises from 45mg to 35mg of sildenafil.

- the first component may for instance comprise 1 Omg of sildenafil and the second component may comprise 40mg of sildenafil.

- the total amount of sildenafil in the first and second components is 25 mg, and the first component comprises from 2.5mg to 7.5mg of sildenafil and the second component comprises from 17.5mg to 22.5mg of sildenafil.

- the first component may for instance comprise 5mg of sildenafil and the second component may comprise 20mg of sildenafil.

- the sildenafil in the first component may be sildenafil free base.

- the sildenafil in the first component may be a pharmaceutically acceptable salt of sildenafil. It may for instance be sildenafil citrate. Alternatively, it may be a fatty acid salt of sildenafil.

- the sildenafil in the first component may be in the form of a co-crystal of sildenafil.

- the dosage of sildenafil quoted on a free base basis, may be as defined above.

- the sildenafil in the second component is often a pharmaceutically acceptable salt of sildenafil.

- Sildenafil citrate is one preferred choice for the second component.

- the sildenafil in the second component may be a fatty acid salt of sildenafil.

- the sildenafil in the second component is sildenafil free base.

- the sildenafil in the second component is in the form of a co-crystal of sildenafil, for instance a co-crystal of sildenafil with a compound which comprises a phenol moiety.

- the dosage of sildenafil quoted on a free base basis, may be as defined above.

- the first component typically comprises from lOmg to 35mg, for instance from lOmg to 30mg, or for instance from 20mg to 25mg, of sildenafil.

- the first component may for instance comprise 20mg of sildenafil.

- the first component may alternatively comprise 25 mg of sildenafil.

- the sildenafil in the first component may be sildenafil free base.

- the sildenafil in the first component may be a pharmaceutically acceptable salt of sildenafil. It may for instance be sildenafil citrate. Alternatively, it may be a fatty acid salt of sildenafil.

- the sildenafil in the first component may be in the form of a co-crystal of sildenafil.

- the dosage of sildenafil quoted on a free base basis, may be as defined above.

- the second component typically comprises from 40mg to 1 OOmg of sildenafil, for in- stance from 40mg to 90mg of sildenafil, or, for example, from 50 mg to 80 mg of sildenafil.

- the second component may for instance comprise 80mg of sildenafil.

- the second component may alternatively comprise 50mg of sildenafil.

- the second component in some embodiments comprises from 70mg to 90mg of sildenafil, for example 80mg of sildenafil.

- the sildenafil in the second component is often a pharmaceutically acceptable salt of sildenafil. Sildenafil cit- rate is one preferred choice for the second component.

- the sildenafil in the second component may be a fatty acid salt of sildenafil.

- the sildenafil in the second component is sildenafil free base.

- the sildenafil in the second component is in the form of a co-crystal of sildenafil, for instance a co-crystal of sildenafil with a compound which comprises a phenol moiety.

- the dosage of sildenafil quoted on a free base basis, may be as defined above.

- the first component may comprise from lOmg to 35mg of sildenafil and the second component may comprise from 40mg to lOOmg of sildenafil.

- the first component may for instance comprise from lOmg to 30mg of sildenafil, and the second component may comprise from 40mg to 90mg of sildenafil.

- the first component may for instance comprise from 20mg to 25mg of sildenafil, and the second component may comprise from 50mg to 80mg of sildenafil.

- the first component may comprise about 20mg of sildenafil and the second compo- nent may comprise about 80mg sildenafil.

- the first component may comprise about 25mg of sildenafil and the second component may comprise about 50mg sildenafil.

- the first component may be adapted to deliver sildenafil rapidly, wherein the adaptation is that the first component comprises sildenafil admixed with excipients in a manner which promotes rapid, preferably immediate, release of the sildenafil.

- the first component may comprise sildenafil admixed with excipients, which may be conventional excipients, which promote immediate release.

- the first component may for instance comprise from lOmg to 35mg, for example from lOmg to 30mg, or from 20mg to 25 mg, of sildenafil with such excipients which promote immediate release. It may for instance comprise 20mg, or 25mg, of sildenafil with such excipients which promote immediate release.

- the excipients may be conventional excipients.

- the sildenafil in the first component may be sildenafil free base.

- the sildenafil in the first component may be a pharmaceutically acceptable salt of sildenafil. It may for instance be sildenafil citrate. Alternatively, it may be a fatty acid salt of sildenafil.

- the sildenafil in the first component may be in the form of a co-crystal of sildenafil.

- the dosage of sildenafil quoted on a free base basis, may be as defined above.

- the second component of the pharmaceutical composition of the invention may comprise sildenafil with excipients, for instance conventional excipients, which promote modified release.

- the second component may for instance comprise from 40mg to lOOmg, for example from 40mg to 90mg, or from 50mg to 80mg, of sildenafil with such excipients which promote modified release. It may for instance comprise 50mg, or 80mg, of sildenafil with such excipients.

- the second component may for instance comprise from 70mg to 90mg, of sildenafil, for instance 80mg sildenafil citrate, with such excipients.

- the excipients may be conventional ex- cipients.

- the excipients which promote modified release in the second component may be polymers.

- the sildenafil in the second component is often a pharmaceutically acceptable salt of sildenafil.

- Sildenafil citrate is one preferred choice for the second component.

- the sildenafil in the second component may be a fatty acid salt of sildenafil.

- the sildenafil in the second component is sildenafil free base.

- the sildenafil in the second component is in the form of a co-crystal of sildenafil, for instance a co-crystal of sildenafil with a compound which comprises a phenol moiety.

- the dosage of sildenafil quoted on a free base basis, may be as defined above.

- sildenafil adapted in a multi component dosage form, such as a tablet, said dosage form being adapted in a first way to provide rapid re- lease of sildenafil into the bloodstream, said dosage form being adapted in a second way to further provide a maintenance dose of sildenafil within the therapeutic window, and the dosage form being adapted in a third way to provide a modified or delayed release format of the sildenafil product which lasts from dose to dose.

- each component is dependent on the choice of formulation but in general the choice of each component will be made so that the amount of active ingredient in each component delivers the right amount of drug product to ensure rapidity, longevity from dose to dose and maintenance of dose within the therapeutic window.

- the total amount of sildenafil in a formulation is at least 20mg and usually 50mg to lOOmg.

- a preferred aspect of the invention is a product (usually a multi component dosage form, such as a tablet) which comprises:

- sildenafil in the form of a co-crystal suitable for rapid release of sildenafil, which co- crystal is optionally as further defined herein;

- a fatty acid salt of sildenafil suitable for delivering sildenafil between onset of action from said rapid release and onset of a bolus amount of a delayed release component; and a delayed release component, comprising a bolus dose of sildenafil.

- the sildenafil in the bolus dose is in the form of sildenafil citrate.

- a product usually a multi component dosage form, such as a tablet

- a product which comprises:

- sildenafil in the form of a co-crystal suitable for rapid release of sildenafil, which co-crystal is optionally as further defined herein;

- sildenafil in the form of a fatty acid salt of sildenafil as defined herein, suitable for delivering sildenafil between onset of action from said rapid release and onset of a bolus amount of a delayed release component;

- said delayed release component comprising a bolus dose of sildenafil.

- the bolus dose of sildenafil may be from 20mg to 95mg sildenafil.

- the sildenafil in the bolus dose may be in the form of sildenafil citrate.

- a product usually a multi component dosage form, such as a tablet

- a product which comprises:

- sildenafil in the form of a co-crystal suitable for rapid release of sildenafil, which co-crystal is optionally as further defined herein; from 2.5 to 15mg sildenafil in the form of a fatty acid salt of sildenafil as defined herein, suitable for delivering sildenafil between onset of action from said rapid release and onset of a bolus amount of a delayed release component; and

- said delayed release component comprising a bolus dose of sildenafil.

- the sildenafil in the bolus dose may be in the form of sildenafil citrate.

- the bolus dose may for example be from lOmg to 80mg sildenafil, for instance 20mg sildenafil.

- Another preferred aspect of the invention is a product (usually a multi component dosage form, such as a tablet) which contains: 5mg of sildenafil co- crystals with a phenol to deliver rapidity, 15mg of sildenafil fatty acid adapted using time release technology to deliver sildenafil between onset of action and kick in of a bolus amount of delayed release component, and a bolus amount of delayed release component of sildenafil which is suitably 20mg.

- sildenafil refers to 80mg sildenafil free base.

- 80mg sildenafil refers to 80mg sildenafil free base.

- the sildenafil is in the form of the citrate salt, the term "80mg sildenafil” as used herein means 112mg of sildenafil citrate (if the mass of the sildenafil citrate is rounded to zero decimal places).

- the term "20mg sildenafil refers to 20mg sildenafil free base.

- sildenafil is in the form of the citrate salt

- the term "20mg sildenafil” as used herein means 28 mg of sildenafil citrate (if the mass of sildenafil citrate is rounded to zero decimal places).

- Fig. 1 shows powder X-ray diffractograms of the initial batch of sildenafil (P42) as received (upper diffractogram) and the published P42 form: QEGTUT anhydrous form (lower diffractogram).

- Fig. 2 shows powder X-ray diffractograms of the initial P42 batch as received (upper diffractogram) and after grinding (lower diffractogram).

- Fig. 3 shows powder X-ray diffractograms of P42 polymorphs P42 Form I (upper diffractogram) and P42 Form II (lower diffractogram).

- Fig. 4 shows powder X-ray diffractograms of P42 polymorphs P42-A (first and top diffractogram), P42-B (second diffractogram), P42-C (third diffractogram), P42-D (fourth diffractogram) and P42-E (fifth and bottom diffractogram).

- Fig. 5 is a diagram summarising the different behaviours of forms of P42.

- Fig. 6 shows powder X-ray diffractograms of the following new multicomponent forms of P42: P42-I-A (first and top diffractogram), P42-I-B (second diffractogram), P42-III (third diffractogram), P42-IV-A (fourth diffractogram), P42-IV-B (fifth diffractogram), P42- V-A (sixth and bottom diffractogram).

- P42-VI-B first and top diffractogram

- P42-VI-C second diffractogram

- P42- VI-D third diffractogram

- P42-VI-E fourth diffractogram

- P42-VII fifth diffractogram

- P42-VIII sixthth diffractogram

- P42-IX sixth and bottom diffractogram

- Fig. 8 shows the dissolution profile of 25mg Viagra tablets in 0.01M hydrochloric acid.

- Fig. 9 shows the dissolution profile of 50mg Viagra tablets in 0.01M hydrochloric acid.

- Fig. 10 shows the dissolution profile of lOOmg Viagra tablets in 0.01M hydrochloric acid.

- Fig. 11 shows the dissolution profile in 0.01M hydrochloric acid of the sustained-release core development formulation no. 16CF25/026 comprising sildenafil citrate, as described in Example 67.

- Fig. 12 shows the dissolution profile in 0.01M hydrochloric acid of the immediate - release development formulation no. 16CF25/027 comprising sildenafil citrate, as described in Example 67.

- Fig. 13 shows the dissolution profile of 25mg Viagra tablets in pH 4.5 phosphate buffer.

- Fig. 14 shows the dissolution profile of 50mg Viagra tablets in pH 4.5 phosphate buffer.

- Fig. 15 shows the dissolution profile of lOOmg Viagra tablets in pH 4.5 phosphate buffer.

- Fig. 16 shows the dissolution profile in pH 4.5 phosphate buffer of the sustained-release core development formulation no. 16CF25/026 comprising sildenafil citrate, as de- scribed in Example 67.

- Fig. 17 shows the dissolution profile in pH 4.5 phosphate buffer of the immediate -release development formulation no. 16CF25/027 comprising sildenafil citrate, as described in Example 67.

- Fig. 18 shows the dissolution profile of 25mg Viagra tablets in pH 6.8 phosphate buffer with 0.125% CTAB.

- Fig. 19 shows the dissolution profile of 50mg Viagra tablets in pH 6.8 phosphate buffer with 0.125% CTAB.

- Fig. 20 shows the dissolution profile of lOOmg Viagra tablets in in pH 6.8 phosphate buffer with 0.125% CTAB.

- Fig. 21 shows the dissolution profile in pH 6.8 phosphate buffer with 0.125% CTAB of the sustained-release core development formulation no. 16CF25/026 comprising sildenafil citrate, as described in Example 67.

- Fig. 22 shows the dissolution profile in pH 6.8 phosphate buffer with 0.125% CTAB of the immediate -re lease development formulation no. 16CF25/027 comprising sildenafil citrate, as described in Example 67.

- Fig. 23 shows the dissolution profile in 0.01M hydrochloric acid of the immediate - release development formulation no. 16CF25/033 comprising sildenafil free base, as described in Example 68.

- Fig. 24 shows the dissolution profile in pH 4.5 phosphate buffer of the immediate -release development formulation no. 16CF25/033 comprising sildenafil free base, as described in Example 68.

- alkyl refers to a linear or branched chain saturated hydrocarbon radical.

- a "C n - m alkyl” refers to an alkyl having from n to m carbon atoms.

- an alkyl group may be a Ci-25 alkyl group, a Ci-24 alkyl group, a Ce-24 alkyl group, a Ci-10 alkyl group, a Ci-6 alkyl group or a C1-4 alkyl group.

- Examples of a Ci-10 alkyl group are methyl, ethyl, propyl, butyl, pentyl, hexyl, heptyl, octyl, nonyl or decyl.

- Ci-6 alkyl groups are methyl, ethyl, propyl, butyl, pentyl or hexyl.

- C1-4 alkyl groups are methyl, ethyl, i-propyl, n-propyl, t-butyl, s-butyl or n-butyl. If the term "alkyl" is used without a prefix specifying the number of carbons anywhere herein, it has from 1 to 4 carbons.

- alkenyl refers to a linear or branched chain hydrocarbon radical comprising one or more double bonds.

- a "C n - m alkenyl” refers to an alkenyl having from n to m carbon atoms.

- an alkenyl group may be a C2-25 alkenyl group, a C2-24 alkenyl group, a Ce-24 alkenyl group, a C2-10 alkenyl group, a C2-6 alkenyl group or a C2-4 alkenyl group.

- Examples of a C2-10 alkenyl group are ethenyl (vinyl), propenyl, butenyl, pen- tenyl, hexenyl, heptenyl, octenyl, nonenyl or decenyl.

- Examples of C2-6 alkenyl groups are ethenyl, propenyl, butenyl, pentenyl or hexenyl.

- Examples of C2-4 alkenyl groups are ethenyl, i-propenyl, n-propenyl, s-butenyl or n-butenyl.

- Alkenyl groups typically comprise one or two double bonds.

- co-crystal (or "co crystal” or “cocrystal”) as used herein means a solid that is a crystalline single phase material comprising two or more different molecular and/or ionic compounds which are neither solvents nor simple salts (S. Aitipamula et al. "Poly- morphs, Salts, and Cocrystals: What's in a Name?", Cryst. Growth Des., 2012, 12 (5), pp

- the two or more different molecular and/or ionic compounds in a co-crystal are generally compounds which are themselves solid at room temperature (i.e. solids at 22 °C). They are typically present in the co-crystal in a definite stoichiometric ratio.

- one of the two or more different molecular and/or ionic compounds is an API, sildenafil, and another of the two or more different molecular and/or ionic compounds is a co-crystal former.

- the co-crystals of the present invention are pharmaceu- tical co-crystals.

- a pharmaceutical co-crystal is a crystalline single phase material comprising an API and one or more unique co-crystal formers, typically in a stoichiometric ratio.

- Each of the one or more co-crystal formers is a molecular or an ionic compound that is a solid at room temperature. Solvates (including hydrates) of an API that do not further comprise a co-crystal former are therefore not considered to be co-crystals.

- a pharmaceutical co-crystal may how- ever include one or more solvent (e.g. acetonitrile, or water) molecules in the crystal lattice which comprises the API and the one or more unique co-crystal formers.

- Co-crystals can be constructed through several types of interaction, including hydrogen bonding (H -bonding), pi stacking, and van der Waals forces.

- H -bonding hydrogen bonding

- pi stacking pi stacking

- van der Waals forces van der Waals forces

- co-crystals often rely on hydrogen-bonded assemblies between neutral molecules of an API and another (co-crystal former) component.

- the dosage forms of the present invention are proven to work as pde5 inhibitors and find use in the treatment of male erectile dysfunction.

- Fresh frozen human penis was obtained from HAM (Pennsylvania). Tissue was thawed at room temperature, the corpus cavernosum was dissected from the penis to yield approximately 2-4 g of tissue and the following isolation protocol was followed. Tissue was coarsely chopped in ice-cold isotonic buffer (35 ml) con- taining 250 mm sucrose, 1 mM EDTA, 0.5 mM PMSF and 20 mM HEPES, pH 7.2, and the mixture subjected to brief (1 min.) treatment with a Silversen mixer/emulsifier.

- Homogenates were prepared using homogeniser tubes with Teflon pestles and a soluble fraction was prepared by centrifugation at 100,000 x g for 60 min. at 4°C. 10 ml of high speed supernatant was applied to a Pharmacia Mono Q anion exchange column (1 ml bed volume) equilibrated with buffer containing 1 mM EDTA, 0.5 mM PMSF and 20 mM HEPES, pH 7.2 (chromatography buffer). The column was then washed with 5 bed volumes of chromatography buffer, after which PDEs were eluted using a continuous gradient of 0-500 mM NaCl (total volume 35 ml) and 1 ml fractions collected.

- Fraction II hydro lysed cGMP and cAMP, with the latter activity being stimulated in the presence of cGMP, and was classified as PDEn, whilst fraction III was cAMP selective and this activity was inhibited in the presence of cGMP, consistent with PDEm activity.

- the above investigation identified three PDE isoenzymes in human corpus cavernosum tissue.

- the predominant PDE was the cGMP-specific PDEv, whilst cGMP- stimulated cAMP PDE n and cGMP-inhibited cAMP PDE m were also present.

- the formulations of the present inventions are tested in vitro and found to be potent and selective inhibitors of the cGMP-specific PDEv.

- relaxation of the corpus cavernosum tissue and consequent penile erection is presumably mediated by elevation of cGMP levels in the said tissue, by virtue of the PDE inhibitory profile of the compounds of the inven- tion.

- the sildenafil summary shows the in vitro dissolution profiles for the two elements of the formulation, the inner sustained release core with 80mg sildenafil and the outer core which is an ODT with 20mg sildenafil.

- Guidance is to place the tablet under the tongue for 60 seconds (see caffeine summary where we tested how much caffeine dissolved by doing this as substitute for Viagra) then swallow the tablet. Described herein is our model of how the tablet dissolves based on different pH levels We assume 20% will go into blood plasma PK from the sublingual element (some will go normal route so even if 30% dissolves not all will go sublingual). This would give us 4mg sublingual which according to other papers could deliver 4 to 5 times the dose in systemic circulation than normal, i.e.

- sildenafil in plasma somewhere around to a normal dose of 100 mg with about 112% to 116% of AUC (so within 505b2 guidelines) modelling and or testing in humans will confirm.

- a two component tablet is preferred the sildenafil summary shows the in vitro dissolution profiles for the two elements of the formulation.

- the present invention relates to novel pharmaceutical formulations, in particular to modified release formulations for the delivery of a therapeutically useful amount of sildenafil.

- Sildenafil citrate (Viagra®) is currently approved for the treatment of erectile dysfunction in male humans.

- Sildenafil is generically described in US patent 5,250,534 as a selective cGMP PDE inhibitor useful in the treatment of cardiovascular disorders such as angina, hypertension, heart failure and atherosclerosis.

- Sildenafil is specifically described in US patent 6,204,383 Bl as an agent with pharmaceutical utility in the treatment of male sexual dysfunction (MED).

- nitric oxide in the corpus cavernosum during sexual stimulation.

- NO nitric oxide

- cGMP cyclic guanosine monophosphate

- Sildenafil has no direct relaxant effect on isolated human corpus cavernosum, but enhances the effect of nitric oxide by inhibiting phosphodiesterase type5 (PDE5), which is re- sponsible for degradation of cGMP in the corpus cavernosum.

- sildenafil When sexual stimulation causes local release of (NO), inhibition of PDE5 by sildenafil causes increased levels of cGMP in the corpus cavernosum, resulting in smooth muscle relaxation and inflow of blood to the corpus cavernosum. Sildenafil at recommended doses has no effect in the absence of sexual stimulation.

- Sildenafil citrate in currently marketed swallow tablets is available in three dosage forms i.e. 25 mg, 50 mg and 100 mg of sildenafil calculated as the free base.

- the time for maximum plasma concentrations of sildenafil is between 0.5 and 2 hours when the patient is in a fasting state, but is delayed, on average, by 1 hour when sildenafil is taken with a high fat meal. After the initial variable delay in the onset of action, a therapeutic effect is maintained for approximately 2 hours, followed by a diminished response for about a further 2 hours.

- sildenafil can result in the inhibition of other phosphodiesterases, for example PDE 2 and PDE 6.

- PDE2 has been linked to the control of cardiac contractility

- PDE6 is found in the retina and is involved in the phototransduction pathway of the retina.

- a common side-effect of sildenafil when delivered by currently marketed swallow tablets is "blue haze", i.e. a transient dose-related impairment of colour discrimination, which is consistent with PDE6 inhibition.

- Warnings are provided on package inserts for existing sildenafil products against administering sildenafil to patients with pre-existing cardiac conditions.

- Sildenafil free base i.e. 5-[2-ethoxy-5-(4-methylpiperazin-l -ylsulfonyl)phenyl]-l- methyl-3-propyl-l,6-dihydro-7H-pyrazolo[4,3-d]pyrimidin-7-one, is specifically described in US patent 6,204,383 Bl .

- Example 1 illustrates the preparation of solid sildenafil by the evaporation of a solution in a mixture of dichloromethane and methanol.

- Examples 2 and 6 describe a solution of sildenafil iodide in dichloromethane, but this is not isolated as a solid product.

- Sildenafil is currently marketed as the citrate salt in numerous countries including the

- Sildenafil citrate is the active ingredient in VIAGRA®, which is approved for use in the treatment of MED.

- VIAGRA® which is approved for use in the treatment of MED.

- the choice of an improved formulation of sildenafil to deliver a clinically optimal dose of sildenafil is not a matter of routine.

- Other PDE5 agents have recently become available on the market for the treatment of MED. These agents include: Cialis®, and Levitra®. These agents have a faster onset of action and longer duration when compared to Viagra®, thereby emphasising the current deficiencies of Viagra®.

- sexual dysfunction is greatly affected and indeed potentiated by stress and other factors including anxiety, uncertainty, time- restrictions, the need for a controlled or limited diet and a clinical environment.

- maximum benefit for the patient is achieved when therapy takes place in as natural an environment as possible, when there is no pressure to keep to a strict timetable as a result of a narrow time-window for therapeutic efficacy, and when there is freedom from distracting side-effects.

- the time interval between dosing and onset of therapeutic efficacy with currently marketed swallow tablets is between 0.5 and 2 hours for fasted healthy male volunteers, and is delayed by a median 60 minutes following a high fat meal. In the general population, this uncertainty is likely to be even greater, and represents a major disadvantage for a stress-free sexual environment. Hence there is a need for a formulation which provides a rapid and predictable onset of therapeutic effect.

- the sharp bolus of sildenafil released into the blood plasma by currently marketed tablets, as described in the art, is undesirable because of the risk of side-effects.

- the target population for therapy includes many people of above middle age who are potentially vulnerable to side-effects associated with cardiac contractility, and who may be tempted to increase the dose beyond the recommended level. Furthermore, even clinically non-significant side- effects such as temporary vision impairment represent unwanted distractions which may increase stress and anxiety.

- sildenafil formulations can be prepared which provide either a rapid and predictable onset of therapeutic efficacy, or a rapid and predictable onset of therapeutic efficacy combined with a prolonged duration of therapeutic efficacy and a control of excessive blood plasma levels and adverse events.

- Such formulations are less affected by fasting and are more suited for use in a relaxed environment which is appropriate to non-clinical sexual activity when compared with the conventional swallow tablets of the prior art.

- the present invention provides a modified release drug delivery dosage form which delivers sildenafil within the therapeutic window either more rapidly than the currently marketed swallow tablets containing sildenafil, or continuously for a long period of time compared to the currently marketed swallow tablets containing sildenafil, or more rap- idly and continuously for a long period of time when compared to currently marketed swallow tablets containing sildenafil.

- the modified release formulation of the present invention is a rapid release, or a delayed release, or a prolonged release formulation, or any combination of the aforementioned, optionally combined with a conventional release component.

- the therapeutic window for sildenafil may also be defined in terms of efficacy and side-effect profile.

- the lower threshold of the therapeutic window is equivalent to the threshold at which an adequate improvement in erectile function is delivered.

- the higher threshold of the therapeutic window is the threshold at which side-effects become unacceptable. It is apparent that the therapeutic window lies between the thresholds at which a substantially undiminished erectile response is achieved.

- the formulations of this invention are provided in a series of dosing strengths for the purposes of dose titration, i.e. they permit an individual patient to commence with a low dose formulation and increase the dose systematically until an optimal effect is achieved. It is a further feature of this invention that the formulations of this invention are designed to provide a release of sildenafil within the above-de- fined therapeutic window.

- sildenafil is to be understood to include sildenafil in the form of the free base and also in the form of a pharmaceutically acceptable salt.

- Sildenafil free base is the compound 5-[2-ethoxy-5-(4-methylpiperazin-l-ylsulfonyl) phenyll- methyl-3-propyl-l,6-dihydro-7H-pyrazolo[4,3-d]pyrimidin-7-one which is the active moiety in ViagraTM.

- pharmaceutically acceptable salt thereof refers to salts which are physically, chemically and physiologically acceptable for either human or veterinary use. It should also be understood that sildenafil or a pharmaceutically acceptable salt thereof includes solutions, amorphous forms, and crystalline forms of sildenafil including solvates, hydrates, co-crystals and polymorphs.

- sildenafil should be released within the therapeutic window over a period of more than 2 and up to 24 hours, for example between 2 hours and 5 hours, preferably between 2 and 10 hours, and more preferably between 0.15 and 24 hours (i.e. from dose to dose).

- rapid release in the context of "modified release”, in the context of this specification, means a formulation by means of which a therapeutic blood plasma concentration of sildenafil is achieved more rapidly than with the swallow tablets of the prior art, particularly in the non-fasted state, and more particularly when taken with a high fat meal.

- delayed release in the context of "modified release”, in the context of this specification, is understood to indicate a formulation that is designed to retard the initial release of drug from the dosage form by a pre-determined interval of time.

- delayed release may be understood to mean retardation of release, when compared to the currently approved product which is described as releasing sildenafil between 0.15 and 2 hours when measured in the fasting state, and one hour longer when taken with a high fat meal.

- Prolonged release in the context of "modified release”, in the context of this specification, may be understood to indicate a formulation that is designed to maintain the release of drug over a period of time that is substantially greater than is achieved in the cur- rently marketed formulation.

- substantially greater means that the drug is released within the therapeutic window for longer than 2 hours with no marked diminution of therapeutic effect. Accordingly, sildenafil is released within the therapeutic window over a period of more than 2 and up to 24 hours, for example between 2 hours and 5 hours, preferably between 2 and 10 hours, and more preferably between 2 and 24 hours. Rapid release formulations may be achieved by several different methodologies, which may be used alone or in combination.

- rapid release may be achieved by a dosage form of sildenafil comprising a rapidly dispersing wafer containing sildenafil or a pharmaceutically acceptable salt thereof which is placed on the tongue and dissolves in the mouth, for example within the buccal fluids.

- the wafer is dispersed and/or dissolved over a period of about 1 to 60 sec- onds, preferably about 1 to 30 seconds, most preferably about 1 to 10 seconds.

- the wafer is made from a freeze-dried compact containing sildenafil or a pharmaceutically acceptable salt thereof, in a matrix of a buccal fluid-dispersible polymer such as gelatine and a polysaccharide such as mannitol.

- Sildenafil is dissolved or dispersed into a suspension of mannitol and gelatine prior to filling into blister cavities. These liquid filled blisters are then conveyed through a liquid nitrogen freezing tunnel for freezing and then into a freeze dryer where the solvent is removed leaving behind a highly porous wafer loaded with sildenafil. Details of this technology are described in the scientific and patent literature, for example W Habib et al in Critical Reviews in Therapeutic Drug Carrier Systems, Vol 17 (1) 61-72 (2000), M J Rathbone, J Hadgraft & M S Roberts in Modified Release Drug Delivery Sys- tems, Marcel Dekker, New York, 2003, US Patent No. 4,642,903 and US Patent No

- rapid release of sildenafil may be provided by the blending and compression of sildenafil with water soluble excipients, such as a sugar such as but not limited to mannitol, and an effervescence agent, at low compression forces.

- water soluble excipients such as a sugar such as but not limited to mannitol

- effervescence agent an effervescence agent

- the low compression forces lead to the formation of a highly porous tablet which disintegrates rapidly. Rapid disintegration is further aided by the inclusion of the effervescence agent, which in the context of this specification is defined as one or more agents which produce carbon dioxide upon contact with buccal, gastric, or intestinal fluids.

- effervescence is derived by the reaction which takes place between alkali metal carbonates or bicarbonates and organic acids such as citric acid or tartaric acid to release carbon dioxide. Effervescence may also result from the inclusion of a carbonate or bicarbonate alone to react with acidic gastrointestinal fluids.

- the porous tablet disperses over a period of about 1 to 60 seconds, preferably about 1 to 45 seconds, most preferably about 1 to 30 seconds.

- sildenafil rapid release of sildenafil may be achieved by blending and compressing sildenafil with a suitable sugar such as but not limited to sucrose which has been melt- spun to form a mass of thin filaments with a high surface area.

- a suitable sugar such as but not limited to sucrose which has been melt- spun to form a mass of thin filaments with a high surface area.

- the resulting tablets are highly porous. Upon contact with buccal fluids, they disintegrate rapidly as the mass of thin filaments dissolves. Details of this technology are described in the scientific and patent literature, for example W Habib et al in Critical Reviews in Therapeutic Drug Carrier Systems, Vol 17 (1) 61-72 (2000) and US Patent No 4,855,326 which are incorporated herein by reference.

- rapid release of sildenafil may be achieved by blending and compressing sildenafil with a low mould ability saccharide (e.g. such as but not limited to lactose and mannitol) which has been granulated using a high mould ability saccharide (e.g. such as but not limited to maltose and maltitol) as a binder.

- a low mould ability saccharide e.g. such as but not limited to lactose and mannitol

- a high mould ability saccharide e.g. such as but not limited to maltose and maltitol

- the resulting tablets possess characteristics which enable them to dissolve rapidly on contact with aqueous fluids, typically within about 1 to 60 seconds, preferably about 1 to 30 seconds, most preferably about 1 to 15 seconds. Details of this technology are described in the scientific and patent literature, for example W Habib et al in Critical Reviews in Therapeutic Drug Carrier Systems, Vol 17 (1) 61 -72 (2000) and US Patent No

- rapid release of sildenafil may be achieved by blending and compress- ing sildenafil with a disintegrating agent (e.g. such as but not limited to carboxymethylcellu- lose) and a swelling agent (e.g. such as but not limited to modified starch, e.g. Sodium Starch Glycolate) to produce a rapidly disintegrable tablet which preferably on contact with aqueous fluids disperses over a period of about 1 to 90 seconds, preferably about 1 to 60 seconds, most preferably about 1 to 30 seconds.

- a disintegrating agent e.g. such as but not limited to carboxymethylcellu- lose

- a swelling agent e.g. such as but not limited to modified starch, e.g. Sodium Starch Glycolate

- a further embodiment of the present invention relates to the use of taste masking agents and flavours, or the use of forms of sildenafil, for example a suitable salt form, which have a pleasant or acceptable taste.

- One way of augmenting the rapid release achievable by a suitable choice of formulation is to utilise a salt of sildenafil which is very soluble in saliva or in gastric fluid.

- Yet another way of augmenting the rapid release achieved by a suitable choice of formulation is to utilise an amorphous form of a salt of sildenafil or sildenafil free base.

- the amorphous or crystalline form of a salt of sildenafil or sildenafil free base may be dispersed or adsorbed in a thin layer over a high surface area inert substrate.

- Suitable substrates include but are not limited to: Amberlite ® XAD-4, Amberlite ® XAD-7, Amberlite ® XAD- 16, AMBERSORB ® 348F, AMBERSORB ® 563, AMBERSORB ® 572, Activated carbon, Activated carbon Darco ®, Activated carbon Darco ® G-60, Activated carbon Darco ® KB, Activated carbon Darco ® KB-B, Activated carbon Norit ®, silica gel high purity grades with high pore volume, for example about 0.75 cc/g and average pore diameter 60A.

- a solution of sildenafil or a sildenafil salt may be prepared by dissolving the free base or a suitable salt thereof in a suitable solvent or by contacting stoichiometric quantities of the acid and base components of the salt in water or in a solvent such as but not limited to metha- nol, ethanol, or dichloromethane or a mixture thereof, for example at a concentration of 1 % to 20% by weight.

- the solution is mixed with the inert substrate as defined above, and the required product is isolated by a by either vacuum evaporation or by spray drying.

- the resulting product has sildenafil or a salt thereof dispersed or adsorbed in a thin layer over a high surface area inert substrate.

- the dissolution of sildenafil salts may also be enhanced by reducing the particle size and hence increasing the surface area, for example by such methods as jet milling, ball milling, controlled spray drying, and supercritical fluid precipitation.

- Jet or fluid energy milling involves the use of high pressure air jets to forcibly collide particles together, suitably within a hollow toroidal mill chamber.

- the high kinetic energy of the air causes particles to impact with other particles with sufficient energy for fracture to occur. This process is repeated until a desired particle size range is obtained.

- the product is suitably removed from the apparatus with a particle size classifier.

- Ball milling of sildenafil salts involves the use of a hollow cylinder rotated along a horizontal longitudinal axis. Inside the cylinder, grinding beads are loaded to a level of 30 to 50% of the chamber volume together with sildenafil salt powder feedstock. The size of the beads depends upon the material being processed and the size of the mill chamber. The chamber is rotated at a suitable velocity to allow the beads to cascade and grind the sildenafil drug particles to a finer and desired size.

- a feature of ball milling is that it can be conducted in the dry state, alternatively in a wet state in which sildenafil feedstock is supplied to the milling chamber as a suspension in a fluid. Drug particles of a fine and defined particle size can be manufactured by means of supercritical fluid precipitation.

- One suitable procedure is rapid expansion of a supercritical solution (RESS), in which sildenafil drug particles are formed as a result of the rapid expansion of a supercritical fluid containing dissolved sildenafil.

- a second procedure is gas anti-solvent recrystallisation (GAS) in which the supercritical fluid acts as an anti-solvent and causes sildenafil precipitation from a solution.

- GAS gas anti-solvent recrystallisation

- SEDS solution enhanced dispersion

- SEDS solution enhanced dispersion

- SEDS solution enhanced dispersion

- Multiple repeti- tions of these techniques is also one method for producing novel polymorphic forms which may have greater aqueous solubility and hence be more suitable for rapid release formulations.

- ultrafine drug particles of sildenafil will have a size profile such that at least 90% by weight of the particles have a maximum diameter no greater than 5 microns. More preferably ultrafine drug particles of sildenafil will have a size profile such that at least 90% by weight of the particles have a maximum diameter no greater than 3 microns. Even more preferably ultrafine drug particles of sildenafil will have a size profile such that at least 90% by weight of the particles have a maximum diameter no greater than 1 micron. Most preferably ultrafine drug particles of sildenafil will have a size profile such that at least 90% by weight of the particles have a maximum diameter no greater than 0.5 microns.

- Dispersants and/or other physical stabilisers may be added to prevent aggregation of ultrafine particles and the consequent reduction in the rate of dissolution.

- suitable dispersants and stabilisers and methods for their use can be found in Dissolution technology, L J Leeson and J T Carstensen (eds), APS, Washington 1974, and C.G. Liversedge et al., Int J Pharm Vol 125, pages 309-313, 1995), which publications are incorporated herein by reference.

- Useful stabilisers include polymers and surfactants e.g. hypromellose, hydroxypro- pylcellulose, mannitol, gelatine, tragacanth, acacia, sorbitan esters, glycerol monostearate, methylcellulose, carboxymethylcellulose, sodium lauryl sulphate, polyvinylpyrrolidone, poly- oxyethylene sorbitan fatty acid esters, polyoxyethylene alkly ethers, polyethylene glycols, block co-polymers of ethylene oxide and propylene oxide.

- surfactants e.g. hypromellose, hydroxypro- pylcellulose, mannitol, gelatine, tragacanth, acacia

- sorbitan esters glycerol monostearate, methylcellulose, carboxymethylcellulose, sodium lauryl sulphate, polyvinylpyrrolidone, poly- oxyethylene sorbitan fatty acid esters, poly

- Delayed release of sildenafil can be achieved by means of a physical barrier or coating which delays exposure of the active material to the buccal, gastric, or intestinal fluids.

- One technique which provides delayed release involves the application of a coating of a fluid resistant barrier to a single dosage unit, or to a multiparticulate dosage unit, for example one composed of beadlets, pellets, spheroids, minitablets and/or granules.

- These coatings can be designed to dissolve at a specific pH range, for example an enteric coating which dissolves at a pH greater than 5.0.

- Typical pH-dependent polymers suitable for coating dosage forms include the following:

- hydroxypropylmethylcellulose phthalate 50 which dissolves at about pH 4.8

- hydroxypropylmethylcellulose phthalate 55 which dissolves at about pH 5.2

- polyvinylacetate phthalate which dissolves at about pH 5.0

- methacrylic acid-methyl methacrylate copolymer (1 : 1) which dissolves at about pH 6.0 methacrylic acid-methyl methacrylate copolymer (2: 1), which dissolves at pH 6.5-7.5 methacrylic acid-ethyl acrylate copolymer (2: 1), which dissolves at about pH 5.5

- hydroxypropylmethylcellulose acetate succinate which dissolves at about pH 7.0

- poly(methylvinylether/maleic acid) monoethylester which dissolves at pH 4.5 -5.0

- poly(methylvinylether/maleic acid)n-butyl ester which dissolves at about pH 5.4

- non-pH-dependant coating may be used, which initially impedes the ingress of aqueous fluid, but subsequently erodes and/or dissolves to expose the active agent to dissolution.

- Typical non-pH-dependent polymers suitable for coating dosage forms (single or multiparticulate) to provide a fluid resistant barrier which subsequently erodes or dissolves include, but are not restricted to acacia, alginate, amylase, beeswax, carboxymethylcellulose, carnuba wax, cellulose acetate, cholesterol, ethylcellulose, fatty acids, gelatine, glyceryl be- henate, glyceryl monostearate, glyceryl monodistearate, glyceryl tripalmitate, hypromellose, hydroxypropylcellulose, hydrogenated vegetable oil, lecithin, methylcellulose, paraffin wax, pectin, polyethylene glycol, polycapro lactone, polyglycolic acid, polylactic acid, polygly

- Delayed release of sildenafil may also be achieved by a fluid resistant barrier which combines one or more pH-dependant polymers optionally with one or more non-pH-depend- ant polymers.

- delayed release dosage forms include enteric coated tablets or enteric coated multiparticulate formulations, in which drug-loaded multi-particulate spheres are coated with methacrylic acid-methyl methacrylate co-polymers such as Eudragit LI 00-55, Eudragit L30D-55, or Eudragit FS 30D or Eudragit S100/S12.5.

- methacrylic acid-methyl methacrylate co-polymers such as Eudragit LI 00-55, Eudragit L30D-55, or Eudragit FS 30D or Eudragit S100/S12.5.

- Such formulations will not release sildenafil in the acidic environment of the stomach but only on exposure to the higher pH typically found in the small and large intestine (pH range 5 to 8).

- An enteric coated tablet illustrating one aspect of this invention may be a single-layer tablet or a multi-layer tablet, such as a bi- or tri-layer tablet, wherein the active agent is present in one or more discrete lay- ers within the compressed tablet form.

- the discrete tablet layers can be arranged to provide modified or non-modified release of active agent.

- General descriptions and methods for the preparation of suitable tablets may be found in Aqueous polymeric coatings for pharmaceutical dosage forms, J W McGinty (ed), Marcel Dekker, 1989, New York, and in in Microencapsulation and related drug processes, P Deasy, Marcel Dekker, 1984, New York, which ref- cations are incorporated herein by reference.

- a capsule can be prepared in which the active dose is provided in the form of sildenafil beads and is divided into two or more parts, each part having a non-pH-depend- ant protective coat of different thickness, which takes a different time to erode.

- Suitable non- pH-dependent coating materials have already been described above. Further information can be found in J R Robinson & V H Lee (eds) in Controlled Drug Delivery, second edition, Marcel Dekker, New York, 1987 , V Ranade & M A Hollinger in Drug Delivery Systems, second edition, CRC Press, Boca Raton, 2004 and M J Rathbone, J Hadgraft & M S Roberts in Modified Release Drug Delivery Systems, Marcel Dekker, New York, 2003 which are incorporated herein by reference.

- Modified release may also be provided in the form of prolonged release.

- a prolonged release dosage form may consist of a matrix dosage unit, such as a hydrophilic and/or an erodible matrix, usually in tablet form. Release from such a unit can be controlled by a number of mechanisms, such as dissolution, erosion, diffusion, osmotic pressure or any combination thereof.

- Embodiment of prolonged release dosage forms may utilise excipients which control sildenafil release by more than one formal mechanism.

- An erosion controlled prolonged release dosage unit can be achieved by compressing sildenafil with a slowly dissolvable and/or erodable polymeric material into a tablet form. Release of sildenafil occurs as the polymer dissolves and/or erodes away.

- Suitable polymers include but are not restricted to glyceryl monostearate, acrylic resins, ethylcellulose, stearyl alcohol, hydroxypropylcellulose, carboxymethylcellulose, hypromellose, methylcellulose, hy- droxyethylmethylcellulose, sodium carboxymethylcellulose.

- a diffusion controlled prolonged release dosage form may be produced by compressing a water-swellable hydrophilic polymer in combination with sildenafil drug substance.

- Such systems are often referred to as "hydrophilic matrices" or “swellable-soluble” systems. Water continues to penetrate the matrix causing the swelling of the hydrophilic polymer. The gelatinous layer that is formed, retards the rate of ingress of water into the matrix and the flux of drug out of the matrix. Sildenafil is released from such matrices either by diffusion through the gel layer or by erosion and/or dissolution of the gel layer.

- Suitable materials would include any pharmaceutically acceptable excipient which can swell and form a gelatinous mass upon hydration, for example, hydroxypropylmethylcellulose, and xanthan gum. Further information and descriptions of such dosage forms can be found in Controlled Drug Delivery, sec- ond edition, J R Robinson & V H Lee (editors), Marcel Dekker, New York, 1987 which publication is incorporated herein by reference.

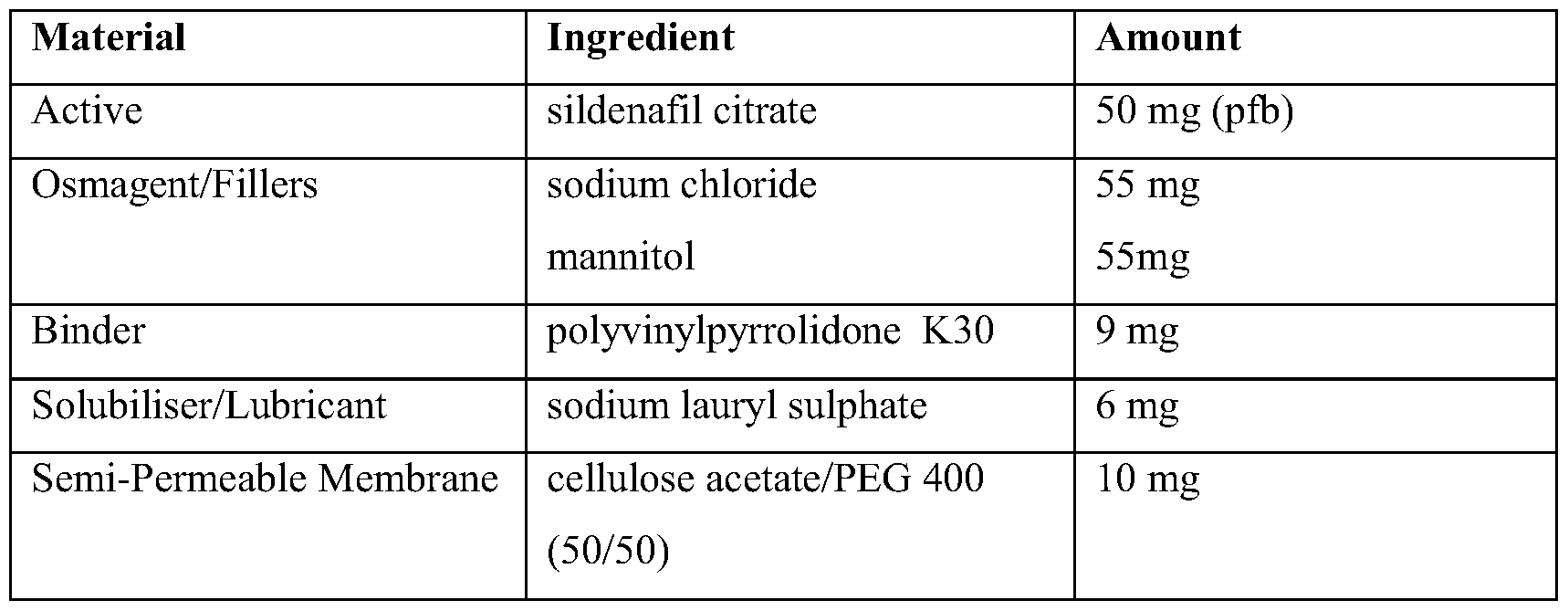

- An osmosis controlled prolonged release dosage form may be produced by compressing sildenafil in combination with an osmagent into a tablet matrix core formulation.

- This matrix core is then in part coated with a semi-permeable membrane in known manner, utilis- ing such polymers such as methacrylates, ethylcellulose, and cellulose acetate.

- Aqueous fluids are drawn by osmosis from the exterior environment across the membrane at a controlled rate into the core, causing dissolution of both sildenafil and the osmogent and increased pressure within the matrix core. The pressure forces the solubilised sildenafil out through a specially created aperture or passageway.

- osmagents include but are not restricted to sodium chloride, potassium chloride, lithium chloride, magnesium chloride, magnesium sulphate, lithium sulphate, sodium sulphate, potassium sulphate, citric acid, mannitol, ribose, arabinose, galactose, leucine, glycine, fructose, sucrose, sodium and other bicarbonates. Further information can be found in the scientific and patent literature, for example: Controlled Drug Delivery, second edition, J R Robinson & V H Lee (editors), Marcel Dekker, New York, 1987, Modified Release Drug Delivery Systems, M J Rathbone, J Hadgraft & M S

- Prolonged release can also be achieved by applying a porous or semipermeable membrane coat onto a tablet surface by the application of such polymers such as methacrylates, ethylcellulose, and cellulose acetate. Release from such systems can occur by more than one of the mechanisms described above, for example a combination of dissolution, diffusion, erosion, and osmosis.

- prolonged release can be achieved by coating multiparticulates with semipermeable membranes.

- the multiparticulates include drug-coated substrates, such as lactose beads, and drug-containing substrates, such as drug-containing lactose spheres.

- compositions of the present invention provide a single modified release formulation of sildenafil or a combination of two or more taken from the various modified and unmodified release forms of sildenafil: rapid release, conventional release, pulsed release, delayed release, and prolonged release. Therefore the compositions of this invention have a component or a combination of components which possess one of the following release characteristics:

- One preferred embodiment of this invention is a formulation in which a dose of sildenafil within the therapeutic window is provided both rapidly and with duration of activity of approximately 2 hours.

- Such a formulation may comprise a rapid release component combined with a conventional release component at a lower dose than would conventionally be necessary.

- Such a formulation is useful to a patient who expects an imminent sexual encounter irrespective of recent food intake, and who wishes to avoid distracting or harmful side-effects.

- Another preferred embodiment of this invention is a formulation in which a dose of sildenafil within the therapeutic window is provided with an initial delay of 0.15 to 2 hours, and with duration of activity of approximately 4 hours.

- Such a formulation may comprise a conventional release component at a lower dose than would conventionally be necessary, combined with a delayed release component.

- Such a formulation is useful to a patient who expects a sexual encounter at a time which is not less than 2 hours in the future, but does not wish to be restricted by recent or imminent food intake, and who wishes to avoid distracting or harmful side-effect

- Another preferred embodiment of this invention is a formulation in which a dose of sildenafil within the therapeutic window is provided both rapidly and with duration of activity of approximately 4 hours.

- a formulation may comprise a rapid release component combined with a conventional release component at a lower dose than would conventionally be necessary, and a delayed release component.

- Such a formulation is useful to a patient who expects an imminent sexual encounter irrespective of recent food intake, but who is uncertain of the exact timing, and who wishes to avoid distracting or harmful side-effects.

- Another preferred embodiment of this invention is a formulation in which a dose of sildenafil within the therapeutic window is provided with an initial delay of 0.15 to 2 hours, and with a duration of activity of approximately 12 hours.

- a formulation may comprise a conventional release component at a lower dose than would conventionally be necessary com- bined with either a prolonged release component or a pulsed release component.

- such a formulation is useful to a patient who expects a sexual encounter at a time which is not less than 2 hours in the future, but is very uncertain of the timing and who does not wish to be restricted by recent or imminent food intake, and who wishes to avoid distracting or harmful side-effects.

- a b.i.d. presentation of this formulation may be employed for the purposes of continu- ous treatment.

- Another preferred embodiment of this invention is a formulation in which a dose of sildenafil within the therapeutic window is provided both rapidly and with a duration of activity of approximately 12 hours.

- a formulation may comprise a rapid release component combined with a conventional release component at a lower dose than would conventionally be necessary, and a prolonged release component.

- Such a formulation is useful to a patient who expects an imminent sexual encounter irrespective of recent food intake, and who wishes to be prepared for sexual activity for an extended period of time, and who wishes to avoid distracting or harmful side-effects.

- Another preferred embodiment of this invention is a formulation in which a dose of sildenafil within the therapeutic window is provided with an initial delay of 0.15 to 2 hours, and with duration of activity of approximately 16-24 hours.

- a formulation may comprise a conventional release component at a lower dose than would conventionally be necessary combined with either a prolonged release component.

- Such a formulation is useful to a patient who expects a sexual encounter at a time which is not less than 2 hours in the future, but is very uncertain of the timing and who wishes to be prepared for sexual activity for an extended period of time, and who does not wish to be restricted by recent or imminent food intake, and who wishes to avoid distracting or harmful side-effects.

- Another preferred embodiment of this invention is a formulation in which a dose of sildenafil within the therapeutic window is provided both rapidly and with a duration of activity of approximately 16-24 hours.

- a formulation may comprise a rapid release component combined with a conventional release component at a lower dose than would conven- tionally be necessary, and a prolonged release component.

- Such a formulation is useful to a patient who expects an imminent sexual encounter irrespective of recent food intake, and who wishes to be prepared for sexual activity for a much extended period of time, and who wishes to avoid distracting or harmful side-effects. It should be appreciated that this approach to providing a variety of specially designed formulations to address specific circumstances is es- pecially useful for over-the-counter products where the patient is able to self-diagnose and choose the most appropriate product for his specific needs.

- these formulations may provide effective therapy for female patients suffering from sexual disorders including but not limited to lack of clitoral arousal. This is especially surprising since the innovator company have reported lack of effi- cacy for sildenafil in female patients.

- the dose of sildenafil calculated as the free base, will be adjusted in consideration of the amount of sildenafil in each component and the total amount so as to ensure that blood plasma levels remain within the therapeutic window whilst achieving the effect desired and described above.

- the quantity of sildenafil required in each component of each formulation can be determined by the skilled worker from the information provided in this invention. Firstly the target pharmacokinetic profile for the formulation is selected in line with the objects of the present invention. Then, from knowledge of the therapeutic window as defined herein, the mean rate of elimination of sildenafil in the body, and the release profile of sildenafil from each component, it is a matter of routine experimentation to establish the necessary quantity of sildenafil in each component.

- each of the formulations of this invention will be provided in a range of strengths to permit titration of dose for individual patients.

- the compositions are in unit dosage form.

- Unit dosage forms for oral administration may be in tablet or capsule form and may as necessary contain conventional ex- cipients such as binding agents, fillers, lubricants, glidants, disintegrants, effervescent agents, and wetting agents.

- binding agents include but are not limited to: acacia, alginic acid, car- boxymethylcellulose calcium, carboxymethylcellulose sodium, dextrin, dextrose, ethylcellu- lose, gelatin, liquid glucose, guar gum, hydroxyethyl cellulose, hydroxypropyl cellulose, hy- droxypropyl methylcellulose, magnesium aluminium silicate, maltodextrin, methyl cellulose, polymethacrylates, polyvinylpyrrolidone, pregelatinised starch, sodium alginate, sorbitol, starch, syrup, tragacanth.

- fillers include but are not limited to: calcium carbonate, calcium phosphate, calcium sulphate, carboxymethylcellulose calcium, carboxymethylcellulose sodium, compressible sugar, confectioner's sugar, dextrates, dextrin, dextrose, dibasic calcium phosphate dihydrate, dibasic calcium phosphate, fructose, glyceryl palmitostearate, glycine, hydro- genated vegetable oil-type 1 , kaolin, lactose, maize starch, magnesium carbonate, magnesium oxide, maltodextrin, mannitol, microcrystalline cellulose, polymethacrylates, potassium chloride, powdered cellulose, pregelatinised starch, sodium chloride, sorbitol, starch, sucrose, sugar spheres, talc, tribasic calcium phosphate, xylitol.

- lubricants include but are not limited to: calcium stearate, glyceryl monostearate, glyceryl palmitostearate, magnesium stearate, microcrystalline cellulose, sodium benzoate, sodium chloride, sodium lauryl sulphate, stearic acid, sodium stearyl fumarate, talc, zinc stearate.

- glidants include but are not limited to: colloidal silicon dioxide, powdered cellulose, magnesium trisilicate, silicon dioxide, talc.

- disintegrants include but are not limited to: alginic acid, carboxymethylcellulose calcium, carboxymethylcellulose sodium, colloidal silicon dioxide, croscarmellose sodium, crospovidone, guar gum, magnesium aluminium silicate, microcrystalline cellulose, methyl cellulose, polyvinylpyrrolidone, polacrilin potassium, pregelatinised starch, sodium alginate, sodium lauryl sulphate, sodium starch glycolate.

- effervescent agents are effervescent couples such as an organic acid and a metal carbonate or bicarbonate.

- Suitable organic acids include but are not limited: citric acid, tartaric acid, malic acid, fumaric acid, adipic acid, succinic acid, and alginic acid, and anhydrides and acid salts.

- Suitable carbonates and bicarbonates include, for example, sodium carbonate, sodium bicarbonate, potassium carbonate, potassium bicarbonate, magnesium car- bonate, sodium glycine carbonate, L-lysine carbonate and arginine carbonate.

- only the base component of the effervescent couple may be present.

- the solid oral compositions may be prepared by conventional methods of blending, filling or tableting.

- the tablets may be coated according to methods known in normal phar- maceutical practice. For example see Pharmaceutical dosage forms: tablets, Volume 1 second edition, H A Lieberman, L Lachman and J B Schwartz (eds) Marcel Dekkker, 1989, New York and G C Cole & J Hogan in Pharmaceutical coating technology, Taylor & Francis, London, 1995 which are herein included by reference.

- Formulations of the present invention may be used for the treatment of human male erectile dysfunction, which method comprises administering a formulation of the present invention comprising an effective amount of sildenafil and/or a pharmaceutically acceptable salt thereof to a sufferer in need thereof.

- Formulations of the present invention may also be used for the treatment of human female sexual dysfunction, which method comprises administering a formulation of the pre- sent invention comprising an effective amount of sildenafil and/or a pharmaceutically acceptable salt thereof to a sufferer in need thereof.

- Formulations of the present invention may also be used in the preparation of a medicament for use in the treatment of human male erectile dysfunction.

- Formulations of the present invention may also be used in the preparation of a medic- ament for use in the treatment of human female sexual dysfunction.

- the present invention also provides a pharmaceutical composition for use in the treatment of human male erectile dysfunction or human female sexual dysfunction in which the pharmaceutical composition is as defined in the present invention.

- Examples 52 to 65 hereinbelow it should be appreciated that the amount of active ingredient is not specified precisely but is readily calculated from a consideration of the target product profile required within the scope of the present invention without undue experimentation.

- the sildenafil citrate used in these examples may be replaced by other salts of sildenafil with compatible solubility properties.

- the present invention also relates to novel compounds and to their use in medical therapy, in particular to their use in the treatment and/or prophylaxis of disorders associated with PDE5 inhibition.

- the present invention also relates to processes for preparing these novel compounds.

- Sildenafil is generically described in US patent 5,250,534 as a selective cGMP PDE inhibitor useful in the treatment of cardiovascular disorders such as angina, hypertension, heart failure and atherosclerosis.

- Sildenafil free base i.e. 5-[2-ethoxy-5-(4-methylpiperazin-l -ylsulfonyl)phenyl]-l- methyl-3- propyl-l,6-dihydro-7H-pyrazolo[4,3-d]pyrimidin-7-one, is specifically described in US patent 6,204,383 Bl as an agent with pharmaceutical utility in the treatment of male sexual dysfunction.

- Sildenafil citrate is the active ingredient in VIAGRA®, which is approved for use in the treatment of MED.

- the choice of a form of a pharmaceutical agent having a basic functional group is not a matter of routine.

- Pfizer the originator company

- markets the citrate salt could lead one skilled in the art to believe that other forms were less preferred since the citrate salt is an unusual choice of salt to market.

- the choice of salts of sildenafil other than the prior art citrate salt is not therefore prima facie obvious in view of this technical prejudice and other concerns about the formation and properties of such salts.

- sildenafil other than the prior art citrate which are pharmaceutically acceptable. Such forms apart from finding use in medical therapy and as useful intermediates are also useful in providing new active ingredients containing the active moiety sildenafil which could form the basis for providing new value-added line extenders in the form of advantageous formulations or new uses.

- salts of sildenafil with certain long chain fatty acids can be prepared and have a pleasant and fully acceptable flavour which permits the use of formulations such as chewable tablets, chewing gum, and oral suspensions.

- the invention accordingly en- compasses such chewable tablets, chewing gum, and oral suspensions, but also is of value in swallow tablets and other conventional formulations. Accordingly, the present invention provides sildenafil salts with long chain fatty acids.

- the yield is established by comparison of the weights of cost-critical starting material and product making allowance for molecular weights and purities. Purities are established by hplc, gc or other conventional analytical method by means of a validated procedure and comparison with a reference standard. See for example Remington: The Science and Practice of Pharmacy 20th edition, Alfonso R Gennaro editor, Lippincott, Williams, and Wilkins, Philadelphia USA, ISBN 0-683-306472, page 597.

- Colour may be defined as the perception or subjective response of an observer to the objective stimulus of radiant energy in the visible spectrum extending over a range 400nm to 700nm in wavelength.

- hue or the quality by which one colour family is distinguished from another, such as red, yellow, blue, green and intermediate terms

- value or the quality that distinguishes a light colour from a dark one

- chroma or the quality that distinguishes a strong colour from a weak one, or the extent to which a colour differs from a grey of the same value.

- the perception of colour and colour matches is dependent on conditions of viewing and illumination. Determinations should be made using diffuse, uniform illumination under conditions that reduce shad- ows and nonspectral reflectance to a minimum.